You are here: Beltron GmbH | Products | Beltrotherm dryer concept | Beltrotherm final curing photo soldermask after exposure and development

Beltrotherm

FINAL CURING PHOTO SOLDERMASK AFTER EXPOSURE

AND DEVELOPEMENT WITH UV-BUMP OPERATION FIRST

BELTROTHERM

FINAL CURING PHOTO SOLDERMASK AFTER EXPOSURE AND DEVELOPEMENT WITH UV-BUMP OPERATION FIRST

UNSER RENNER, EXTREM LANGLEBIG, WARTUNGSARM, ENERGIESPAREND, BEDIENERFREUNDLICH!

Product description:

Double-sided Final Curing Line for soldermask

Pos 1: Feeder

Pos 2: UV-bump double-sided

Pos 3: BELTROTHERM-dryer doulbe-sided

Pos 4: Stacker

The line is working fully automatic after loading in 3-shift operation without supervision.

The length of the BELTROTHERM-dryer is designed according to capacity requirements.

The high-end properties of the solder mask to prevent undercutting in aggressive chemical processes and offer maximum durability in multiple soldering processes.

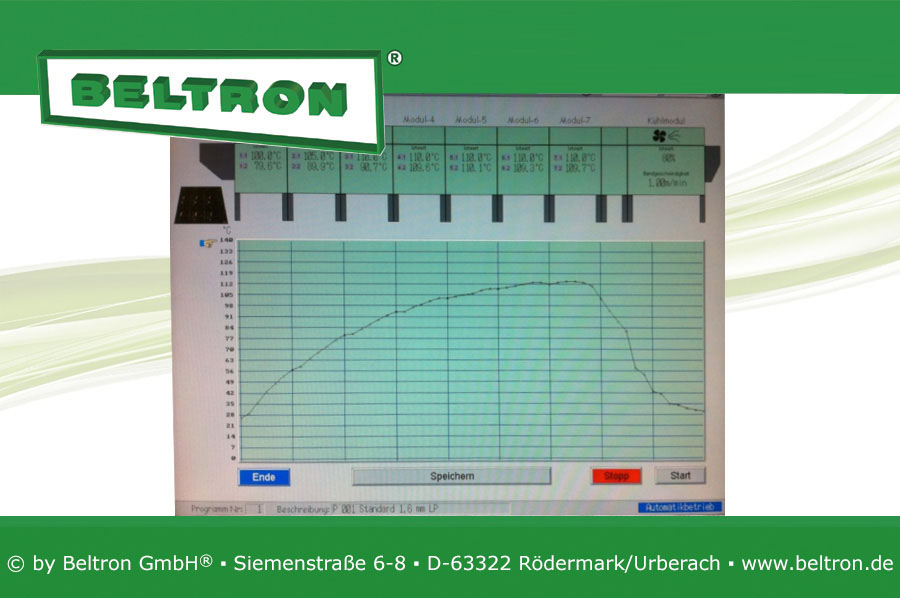

For different PCB thickness ranges and special types of temperature profiles - tuned to an optimal drying process – are created and stored in the PLC. Optimized temperature profiles are recorded and stored in up to 120 programs.

The appropriate drying program is called by touch on the touch screen and changed within minutes. The few minutes changeover usually go into the preparation of the coating line for the new lot. The operational readiness will be reported by signal to the upstream machine. The touch screen OMRON PLC shows a clear view of the operation condition and is ready for more input.

Our Technology and Sales-Partner in Electronic Industry

ahk GmbH · Gewerbering 8 - 13 · 74193 Schwaigern · Germany

Tel.: +49 (0)7138 - 81274-0 · Fax: +49 (0)7138 - 81274-10

Email: info@ahk-service.de · Internet: www.ahk-service.de

Details of our high-performance

Thermo Dryer Beltrotherm:

+ Ballast ( 100% and 50% adjustable)

+ UV lamp with or without

pneumatic shutter

+ Air-coded housing with

aluminium reflector

Details BELTRON

Thermo Dryer

BeLtrotherm Details of our

high-performance

Thermo Dryer Beltrotherm

Beltron Thermo Dryer Beltrotherm have many key benefits for you and your production, take advantage of our quality benefits:

+ over 55 Years quality "Made in Germany"

+ Innovative UV technology

+ Complete, even drying

+ Very short drying times

+ Sustainable energy-saving systems

+ Further processing possible immediately

+ Highly scratch-resistant and shiny

+ Durable & increased chemical resistance

BELTRON Thermo Dryer Beltrotherm

are used successfully in:

+ printing industry

+ electronic industry

+ plastic industry

+ textile industry

+ packaging industry

+ glass industry

advantage BELTRON

Thermo Dryer

Beltrotherm Advantages of our

high-performance

Thermo Dryer Beltrotherm

applications BELTRON

Thermo Dryer

BeLtrotherm Uses of our

high-performance

Thermo Dryer Beltrotherm

The Thermo-Dryer BELTROTHERM are used successfully in:

These are just a few examples from the various partner portfolio of Beltron.

- printing industry

- electronic industry

- plastic industry

- textile industry

- packaging industry

- automotive industry

- glass industry

Working widths: 610 mm / 24" or 760 mm / 30"

Belt speed: adjustable

Tack drying soldermask: 0,5 - 50,0 m/min.

Curing soldermask: 0,2 - 2,0 m/min.

Curing paste: 0,5 - 5,0 m/min.

Temperature range: RT - 250°C

Electrical connection: 400 V 3/N/PE 50 Hz

Connecting power per module: 9,3 kW / 18,6 kW

Working power per module: 4,6 kW / 9,3 kW

Supply air, exhaust air per Module 100 - 300 m³/h

Module length: 1000 mm

Module width: 1000 mm

Module height: 1200 mm

Available modules:

tranquilizers module

Abdunstmodul

heating module

cooling module

Inlet / outlet, various

PLC control: In the mobile console with touch-screen screen

Information

Beltrotherm

Advice to Thermo dryer Beltrotherm:

Phone: +49 6074 - 89199-0 or E-Mail: info@beltron.de

Contactform - Thermo dryer Beltrotherm